Inventory management plays a critical role in the success of any business that deals with physical products. Efficient inventory management can increase profits, reduce waste, and enhance customer satisfaction. Understanding how to analyze inventory levels for optimal operational efficiency is a key component of mastering inventory management.

Businesses must ensure that their inventory levels are neither too high nor too low. Excess inventory can tie up valuable resources and increase holding costs, while insufficient inventory can lead to stockouts and lost sales. Implementing effective analytical techniques is essential for achieving the right balance and maximizing operational efficiency.

Understanding Inventory Management Basics

Before delving into analysis methods, it’s crucial to grasp the fundamentals of inventory management. At its core, inventory management involves overseeing the flow of goods from manufacturers to warehouses and from these facilities to points of sale. It aims to ensure that a business always has the right products in the right quantity at the right time. This process is not merely about keeping track of stock; it also encompasses the strategic planning necessary to align inventory levels with market demand, seasonal trends, and promotional activities.

Key Concepts in Inventory Management

Several key concepts underpin inventory management, including stock levels, order points, and lead times. Stock levels refer to the amount of inventory a business holds at any given time, while order points are the predetermined levels at which new stock is ordered. Understanding lead times—the duration between ordering and receiving stock—is essential for maintaining optimal stock levels. Businesses must also consider safety stock, which acts as a buffer against unexpected demand spikes or supply chain disruptions, ensuring that operations continue smoothly even in unpredictable circumstances.

Another important concept is the inventory turnover ratio, which measures how often inventory is sold and replaced over a period. A high turnover rate indicates efficient operations, while a low rate may suggest overstocking or inefficiencies. Additionally, businesses often utilize various inventory management techniques, such as Just-In-Time (JIT) or Economic Order Quantity (EOQ), to optimize their inventory processes. These techniques help minimize holding costs while ensuring that inventory levels are aligned with customer demand.

Importance of Inventory Analysis

Inventory analysis is vital for identifying potential issues and opportunities for improvement. By thoroughly analyzing inventory data, businesses can make informed decisions that enhance efficiency and profitability. Regular analysis helps identify slow-moving items, allowing businesses to adjust their strategies accordingly. For instance, if certain products are consistently underperforming, companies might consider discounting these items or bundling them with more popular products to boost sales.

Additionally, effective inventory analysis can aid in demand forecasting, enabling businesses to anticipate customer needs and optimize stock levels. This ensures that products are available when needed, enhancing customer satisfaction and loyalty. Advanced analytics tools can further refine this process by utilizing historical sales data and market trends to predict future demand more accurately. By leveraging technology, businesses can not only streamline their inventory processes but also create a more responsive supply chain that adapts to changing consumer preferences and market dynamics.

Setting Inventory Goals

Setting clear inventory goals is an important step in achieving operational efficiency. These goals should align with the overall business objectives and consider factors such as customer demand, market conditions, and financial constraints. By taking a strategic approach to inventory management, companies can not only enhance their operational performance but also create a more resilient supply chain capable of adapting to changing market dynamics.

Aligning Inventory with Business Objectives

To align inventory with business objectives, companies should first identify their key performance indicators (KPIs) related to inventory, such as inventory turnover rates and order accuracy. These KPIs should reflect broader business goals, such as revenue growth or improved customer service levels. For instance, a retail business may track the rate at which products are sold versus the rate at which they are restocked, providing insights into customer preferences and inventory efficiency.

Once KPIs are established, businesses can implement inventory strategies that support these objectives. For example, a company aiming to improve delivery speed may focus on reducing lead times or increasing stock levels of high-demand items. Additionally, leveraging technology such as inventory management software can provide real-time data analytics, enabling businesses to make informed decisions and quickly adjust their inventory strategies based on current trends and consumer behavior.

Defining Optimal Inventory Levels

Defining optimal inventory levels involves determining the ideal balance between having enough stock to meet demand and minimizing excess inventory. Businesses must take into account factors such as seasonal fluctuations, supplier reliability, and economic conditions. Understanding these variables allows companies to forecast demand more accurately and adjust their inventory accordingly, thus avoiding both stockouts and overstock situations that can tie up valuable resources.

One approach to defining optimal inventory levels is to establish reorder points, which signal when new stock should be ordered. Safety stock levels—extra inventory kept on hand to prevent stockouts—are also crucial for ensuring smooth operations. By carefully calculating and regularly reviewing these levels, businesses can maintain optimal inventory conditions. Furthermore, utilizing techniques such as Just-In-Time (JIT) inventory can help streamline operations by reducing holding costs while ensuring that products are available when needed. This proactive management of inventory not only enhances efficiency but also contributes to overall customer satisfaction by ensuring that products are readily available to meet consumer demand.

Methods for Analyzing Inventory Levels

Various methods exist for analyzing inventory levels, each offering unique insights and benefits. Implementing a combination of these methods can provide a comprehensive view of inventory performance and potential areas for improvement.

ABC Analysis

ABC analysis categorizes inventory items into three groups—A, B, and C—based on their value and importance. ‘A’ items are high-value products that require close monitoring, ‘B’ items are moderate-value products, and ‘C’ items are low-value products.

This method allows businesses to prioritize their focus and resources on the most critical inventory items, ensuring that high-value products are always available. By reallocating resources according to this categorization, companies can improve inventory efficiency and reduce costs. Additionally, ABC analysis can facilitate better decision-making regarding inventory replenishment strategies, as it highlights which items warrant more frequent reviews and adjustments. For instance, a company may decide to implement stricter reorder points for ‘A’ items, while adopting a more relaxed approach for ‘C’ items, thus optimizing the overall inventory management process.

Just-In-Time (JIT) Inventory

The Just-In-Time (JIT) inventory method aims to minimize inventory holding costs by ordering and receiving stock only as it is needed. This approach requires a strong relationship with suppliers and accurate demand forecasting to avoid stockouts.

JIT can significantly reduce waste and improve cash flow, but it also presents challenges, such as vulnerability to supply chain disruptions. Businesses must weigh the benefits and risks before adopting this method. Furthermore, successful implementation of JIT often necessitates an investment in technology and systems that enhance real-time tracking and communication with suppliers. Companies may also need to train their staff on agile inventory practices to ensure everyone is aligned with the JIT philosophy, which emphasizes flexibility and responsiveness to changing market demands. As a result, while JIT can streamline operations, it also requires a cultural shift within the organization to fully realize its potential.

Economic Order Quantity (EOQ)

Economic Order Quantity (EOQ) is a method designed to determine the optimal order size that minimizes total inventory costs. These costs include ordering, holding, and stockout costs. By calculating EOQ, businesses can find the most cost-efficient quantity of products to order.

Implementing EOQ can lead to more consistent ordering practices and reduced overall costs. However, businesses need accurate demand forecasts and cost data to effectively use this method. Moreover, EOQ can be particularly beneficial for companies with stable demand patterns, as it allows them to maintain a balance between inventory carrying costs and order fulfillment efficiency. In dynamic markets, companies may need to adjust their EOQ calculations regularly to account for fluctuations in demand or changes in supplier pricing. Additionally, integrating EOQ with inventory management software can automate calculations and provide real-time insights, further enhancing the decision-making process related to inventory purchases.

Tools and Technologies for Inventory Analysis

Modern inventory management relies heavily on advanced tools and technologies to enhance accuracy and efficiency. These technologies provide real-time insights into inventory levels, streamline processes, and facilitate informed decision-making.

Inventory Management Software

Inventory management software enables businesses to track inventory levels, orders, and sales from a centralized platform. It provides real-time data and analytics that help identify trends, optimize stock levels, and improve decision-making.

By automating routine tasks and providing valuable insights, inventory management software enhances operational efficiency and ensures that businesses can quickly respond to changes in demand.

Automation and AI in Inventory Management

Automation and artificial intelligence (AI) are revolutionizing inventory management by automating repetitive tasks and providing predictive insights. AI algorithms can analyze vast amounts of data to forecast demand more accurately, optimize reorder points, and suggest strategic adjustments.

Implementing AI-driven tools helps businesses reduce manual errors, enhance accuracy, and improve overall inventory performance. These technologies also support scalable growth by enabling companies to manage larger and more complex inventories.

Measuring Inventory Performance

To ensure ongoing improvement, businesses must regularly measure inventory performance against established goals and KPIs. This allows them to identify areas of success and opportunities for further enhancement.

Key Performance Indicators (KPIs)

Key Performance Indicators (KPIs) for inventory management include metrics such as inventory turnover, order accuracy, and stockout rates. These indicators provide insight into how well a business manages its inventory and helps track progress toward achieving inventory goals.

Regularly assessing KPIs enables businesses to gauge the effectiveness of their inventory strategies and make data-driven adjustments. This process ensures continuous improvement and alignment with business objectives.

Inventory Turnover Ratio

The inventory turnover ratio measures how often a company sells and replaces its inventory over a specified period. A high turnover ratio indicates efficient inventory management, while a low ratio may suggest problems with excess stock or inadequate sales.

By monitoring the inventory turnover ratio, businesses can identify trends, assess the effectiveness of their inventory strategies, and make informed decisions to optimize their operations. Properly managing this ratio is crucial for maintaining competitiveness and ensuring long-term success in the marketplace.

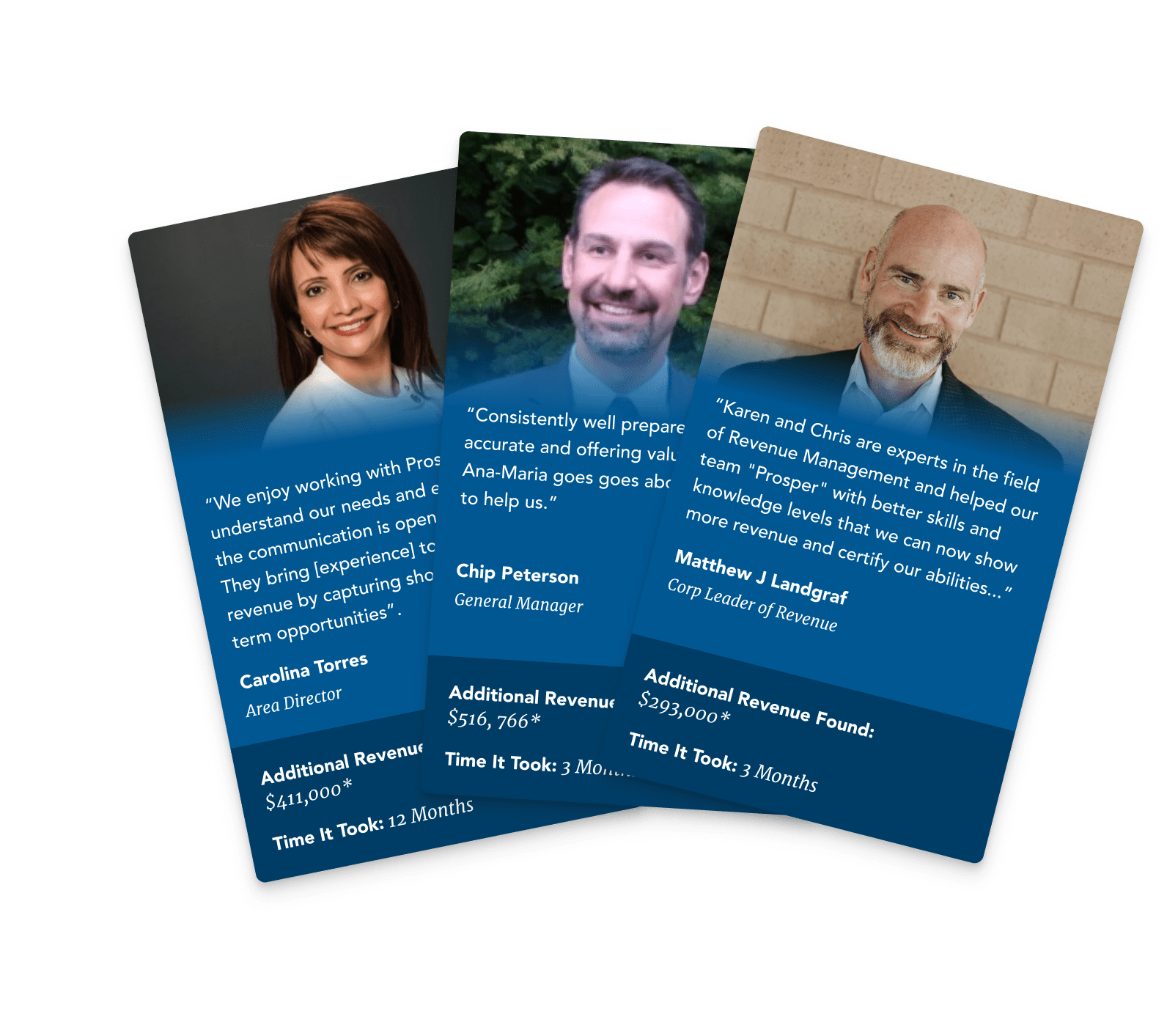

Optimize Your Hotel’s Inventory Management with Prosper Hotels

At Prosper Hotels, we understand the importance of maintaining the perfect balance in your inventory to drive operational efficiency and revenue growth. Our tailored solutions in revenue management, digital marketing, and group housing services are designed to ensure your hotel’s success. Let our team of experts help you optimize your inventory levels and achieve your business goals. Learn More about how we can support your hotel’s journey towards maximum potential.

Drive More Hotel Revenue

Through Untapped Strategies

Drive More Hotel Revenue

Through Untapped Strategies